Understanding the MAP Sensor: A Vital Component in Engine Performance

Related Articles: Understanding the MAP Sensor: A Vital Component in Engine Performance

Introduction

In this auspicious occasion, we are delighted to delve into the intriguing topic related to Understanding the MAP Sensor: A Vital Component in Engine Performance. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

Understanding the MAP Sensor: A Vital Component in Engine Performance

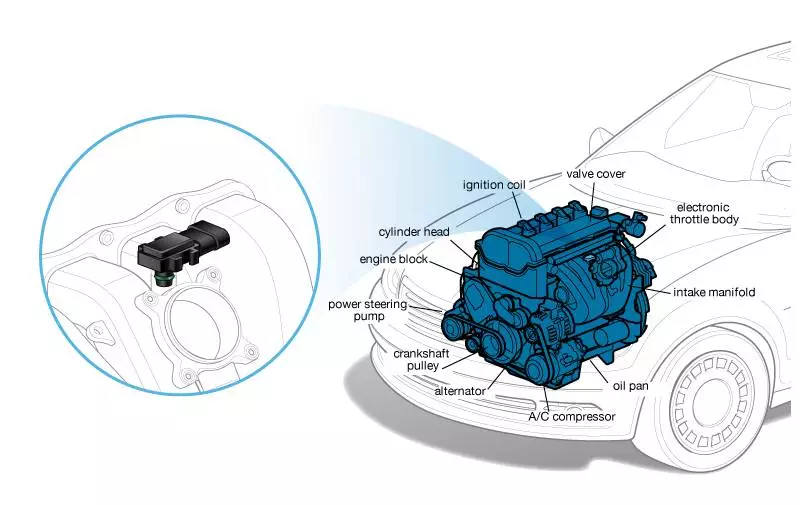

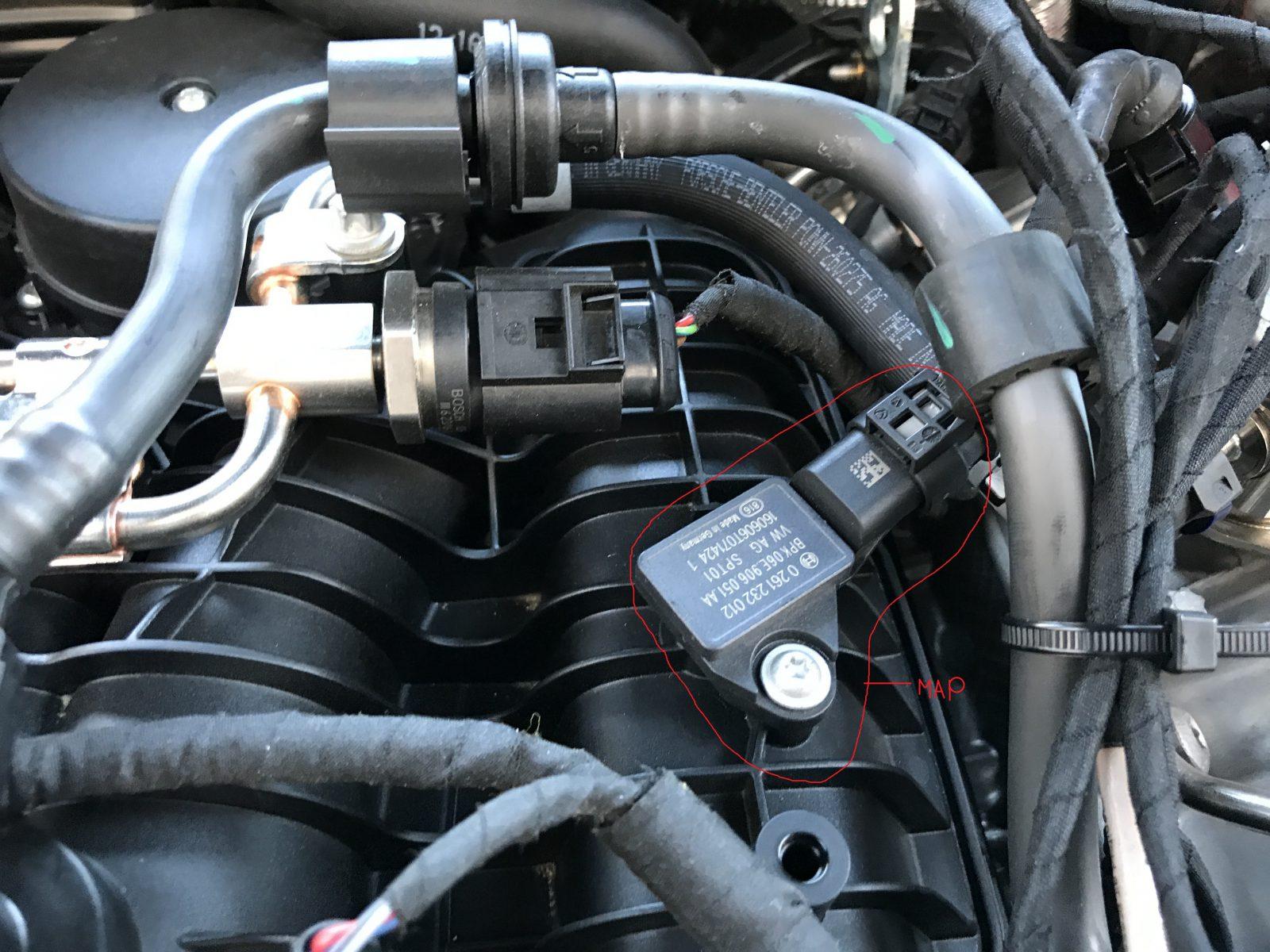

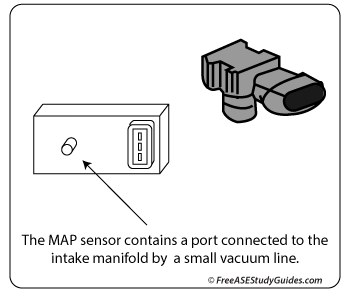

The Manifold Absolute Pressure (MAP) sensor, a crucial element in modern automotive engine management systems, plays a vital role in ensuring optimal engine performance and fuel efficiency. This sensor, typically located on the intake manifold, measures the pressure within the intake manifold, providing the engine control unit (ECU) with critical data to calculate the appropriate amount of fuel and air required for combustion.

The Importance of the MAP Sensor:

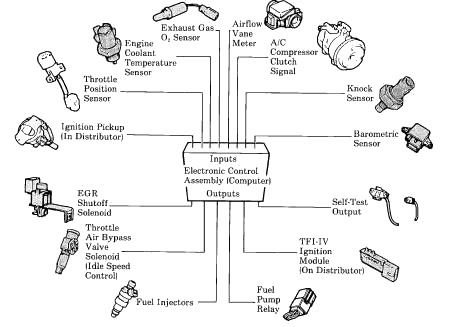

The MAP sensor acts as the "eyes" of the ECU, providing real-time information about the air pressure within the intake manifold. This information is essential for the ECU to:

- Calculate the Engine Load: The ECU uses the MAP sensor reading to determine the engine’s current load, which is essentially the amount of work the engine is performing. This load can vary significantly depending on factors such as throttle position, engine speed, and the demands placed on the vehicle.

- Adjust Fuel Injection: Based on the calculated engine load, the ECU adjusts the fuel injection system to deliver the precise amount of fuel required for optimal combustion. This ensures that the engine receives the correct air-to-fuel ratio, maximizing power and minimizing emissions.

- Control Ignition Timing: The MAP sensor reading also helps the ECU determine the ideal ignition timing. This timing affects the combustion process, influencing engine performance, fuel efficiency, and emissions.

- Monitor Boost Pressure (Turbocharged Engines): In turbocharged engines, the MAP sensor plays a critical role in monitoring boost pressure, ensuring that the turbocharger operates within safe parameters.

Signs of a Faulty MAP Sensor:

A malfunctioning MAP sensor can lead to a range of issues, impacting the engine’s performance and fuel efficiency. Common symptoms of a faulty MAP sensor include:

- Rough Idle: The engine may exhibit rough idling, stalling, or hesitation, especially at low RPMs.

- Poor Acceleration: The vehicle may experience sluggish acceleration, lacking power, or experiencing difficulty climbing hills.

- Increased Fuel Consumption: A faulty MAP sensor can lead to an over-rich fuel mixture, resulting in increased fuel consumption.

- Check Engine Light: The check engine light may illuminate, indicating a fault code related to the MAP sensor.

- Black Smoke from Exhaust: In some cases, a faulty MAP sensor can cause excessive fuel to be injected, leading to black smoke from the exhaust.

Cleaning and Replacing the MAP Sensor:

While a faulty MAP sensor typically requires replacement, cleaning the sensor can sometimes resolve minor issues. However, cleaning the sensor is not a guaranteed solution and should only be attempted as a last resort before replacing the sensor.

Cleaning the MAP Sensor:

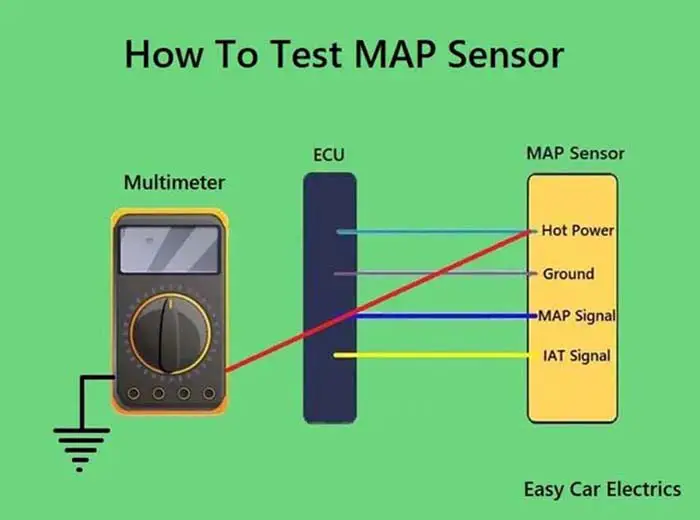

- Disconnecting the Sensor: Begin by disconnecting the electrical connector from the MAP sensor.

- Cleaning the Sensor: Use a spray cleaner specifically designed for electronic components, such as electrical contact cleaner. Avoid using harsh chemicals or solvents that could damage the sensor.

- Drying the Sensor: Allow the sensor to air dry completely before reconnecting it.

- Reconnecting the Sensor: Once dry, carefully reconnect the electrical connector to the sensor.

- Testing the Sensor: After cleaning, start the engine and observe if the symptoms have improved.

Replacing the MAP Sensor:

If cleaning the sensor does not resolve the issues, replacing the sensor is typically the best course of action. This process generally involves:

- Disconnecting the Sensor: Disconnect the electrical connector from the MAP sensor.

- Removing the Sensor: Depending on the vehicle model, the MAP sensor may be secured with a bolt, clamp, or other fastening mechanism. Carefully remove the sensor from its mounting location.

- Installing the New Sensor: Install the new MAP sensor in the same location as the old one, ensuring that it is properly secured.

- Reconnecting the Sensor: Reconnect the electrical connector to the new sensor.

- Clearing Fault Codes: After installation, use a diagnostic tool to clear any fault codes related to the MAP sensor.

FAQs Regarding Cleaning and Replacing the MAP Sensor:

Q: How often should I clean or replace the MAP sensor?

A: The frequency of cleaning or replacing the MAP sensor depends on several factors, including driving conditions, environmental factors, and the vehicle’s age. It is generally recommended to inspect and clean the sensor every 30,000 miles or as part of routine maintenance. However, if you suspect a faulty MAP sensor, inspect and clean or replace it immediately.

Q: Can I clean the MAP sensor with brake cleaner?

A: Using brake cleaner on the MAP sensor is not recommended. Brake cleaner is a harsh solvent that can damage the sensor’s delicate components. Instead, use a cleaner specifically designed for electronic components.

Q: What are the signs of a faulty MAP sensor?

A: The most common signs of a faulty MAP sensor include rough idling, poor acceleration, increased fuel consumption, and the check engine light illuminating.

Q: Is it difficult to replace the MAP sensor?

A: Replacing the MAP sensor is generally a straightforward process, but the level of difficulty can vary depending on the vehicle model and the location of the sensor. Consult your vehicle’s owner’s manual or a qualified mechanic for specific instructions.

Q: Can I drive my car with a faulty MAP sensor?

A: It is not recommended to drive your car with a faulty MAP sensor. A malfunctioning sensor can negatively impact the engine’s performance, fuel efficiency, and emissions.

Tips for Cleaning and Replacing the MAP Sensor:

- Use a Clean Workspace: Ensure that the area where you are working is clean and free of debris to prevent contamination.

- Disconnect the Battery: Before working on the electrical components, disconnect the battery to prevent accidental shocks.

- Refer to the Owner’s Manual: Consult your vehicle’s owner’s manual for specific instructions on accessing and replacing the MAP sensor.

- Use a Torque Wrench: When tightening the sensor, use a torque wrench to ensure that the sensor is properly secured without overtightening.

- Clear Fault Codes: After replacing the sensor, use a diagnostic tool to clear any fault codes related to the MAP sensor.

Conclusion:

The MAP sensor plays a vital role in ensuring optimal engine performance and fuel efficiency. While cleaning the sensor can sometimes resolve minor issues, replacing the sensor is often necessary to restore proper functionality. Regular inspection and maintenance of the MAP sensor are essential for maintaining the health and longevity of your vehicle’s engine. By understanding the importance of this sensor and addressing any potential issues promptly, you can ensure that your vehicle operates smoothly and efficiently.

Closure

Thus, we hope this article has provided valuable insights into Understanding the MAP Sensor: A Vital Component in Engine Performance. We appreciate your attention to our article. See you in our next article!