Unveiling the Dynamics of Airflow: A Comprehensive Guide to Manifold Absolute Pressure and Turbo Boost Sensors

Related Articles: Unveiling the Dynamics of Airflow: A Comprehensive Guide to Manifold Absolute Pressure and Turbo Boost Sensors

Introduction

With great pleasure, we will explore the intriguing topic related to Unveiling the Dynamics of Airflow: A Comprehensive Guide to Manifold Absolute Pressure and Turbo Boost Sensors. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

Unveiling the Dynamics of Airflow: A Comprehensive Guide to Manifold Absolute Pressure and Turbo Boost Sensors

Within the intricate network of sensors that govern a modern engine’s performance, two crucial components stand out: the Manifold Absolute Pressure (MAP) sensor and the Turbo Boost sensor. These seemingly similar entities play distinct roles in the delicate dance of air intake and fuel delivery, ultimately shaping the engine’s power output and efficiency. Understanding their individual functions and the interplay between them is vital for discerning drivers and mechanics alike.

The Manifold Absolute Pressure (MAP) Sensor: A Window into Intake Air Density

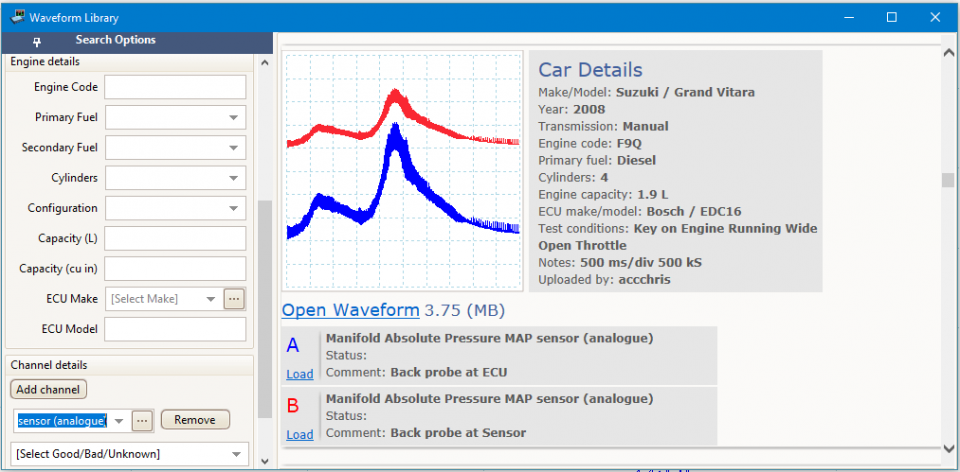

The MAP sensor, a vital component in both naturally aspirated and turbocharged engines, acts as a pressure gauge, meticulously measuring the absolute pressure within the engine’s intake manifold. This pressure, a direct reflection of the density of the air entering the cylinders, provides the engine control unit (ECU) with crucial information for calculating the appropriate fuel injection timing and duration.

How It Works:

The MAP sensor, often a small, cylindrical device, employs a diaphragm that responds to changes in intake manifold pressure. This diaphragm, connected to a variable resistor, alters the electrical resistance based on the pressure. The ECU interprets these changes in resistance, translating them into precise pressure readings.

Importance:

The MAP sensor’s role is paramount in achieving optimal engine performance. By providing the ECU with real-time data on intake air density, it enables:

- Precise Fuel Delivery: The ECU utilizes the MAP sensor readings to determine the ideal amount of fuel to inject for each combustion cycle, ensuring efficient combustion and minimizing fuel waste.

- Accurate Ignition Timing: The MAP sensor also aids in optimizing ignition timing, ensuring the spark occurs at the most opportune moment for maximum power and efficiency.

- Adaptive Control: The ECU can dynamically adjust fuel and ignition parameters based on variations in engine load, altitude, and temperature, thanks to the continuous feedback from the MAP sensor.

The Turbo Boost Sensor: A Gauge of Turbocharger Performance

In contrast to the MAP sensor, which measures the pressure within the intake manifold regardless of the engine’s configuration, the Turbo Boost sensor specifically monitors the pressure generated by a turbocharger. It acts as a vital link between the turbocharger and the ECU, allowing for precise control of boost pressure and optimizing engine performance.

How It Works:

The Turbo Boost sensor, typically a diaphragm-based device, is connected to the turbocharger’s outlet, measuring the pressure of the air forced into the intake manifold by the turbocharger. Similar to the MAP sensor, the diaphragm’s displacement, linked to a variable resistor, translates into electrical resistance changes, which the ECU interprets as pressure readings.

Importance:

The Turbo Boost sensor plays a pivotal role in turbocharged engines, enabling:

- Boost Pressure Control: The ECU uses the Turbo Boost sensor readings to regulate the amount of boost pressure generated by the turbocharger, preventing overboost and ensuring safe and efficient operation.

- Boost Control Valve Management: The Turbo Boost sensor data allows the ECU to precisely control the boost control valve, a vital component that regulates the amount of exhaust gas flowing through the turbocharger, thereby controlling boost pressure.

- Engine Protection: The Turbo Boost sensor serves as a safety mechanism, alerting the ECU to potential overboost conditions, which can lead to engine damage.

The Interplay: A Symphony of Airflow Management

While the MAP and Turbo Boost sensors operate independently, they work in concert to ensure optimal airflow management in turbocharged engines. The MAP sensor provides a comprehensive view of intake manifold pressure, while the Turbo Boost sensor specifically monitors the pressure generated by the turbocharger.

The ECU, leveraging data from both sensors, orchestrates a delicate balance:

- Boost Pressure Control: The ECU uses the Turbo Boost sensor readings to control the boost control valve, ensuring the desired boost pressure is maintained while avoiding overboost.

- Fuel Delivery Adjustment: The ECU, informed by the MAP sensor’s readings, adjusts fuel injection timing and duration to accommodate the increased air density resulting from turbocharging.

- Engine Protection: The ECU utilizes data from both sensors to monitor for overboost conditions and intervene to prevent engine damage.

Understanding the Differences: A Comparative Analysis

While both MAP and Turbo Boost sensors play crucial roles in engine management, their distinct functions and applications set them apart:

| Feature | MAP Sensor | Turbo Boost Sensor |

|---|---|---|

| Function | Measures absolute pressure within the intake manifold | Measures pressure generated by the turbocharger |

| Application | Naturally aspirated and turbocharged engines | Turbocharged engines only |

| Data Usage | Provides comprehensive intake manifold pressure information to the ECU | Provides specific data on turbocharger performance to the ECU |

| Influence on Engine Control | Crucial for fuel delivery, ignition timing, and overall engine management | Essential for boost pressure control, engine protection, and turbocharger efficiency |

FAQs: Unraveling the Mysteries

Q: Can a MAP sensor be used in a turbocharged engine?

A: Yes, a MAP sensor is typically used in a turbocharged engine alongside a Turbo Boost sensor. The MAP sensor provides the ECU with general intake manifold pressure information, while the Turbo Boost sensor specifically monitors the pressure generated by the turbocharger.

Q: What happens if the MAP sensor fails?

A: A failing MAP sensor can lead to various issues, including:

- Poor fuel economy: The ECU, lacking accurate intake manifold pressure data, may deliver an incorrect amount of fuel, leading to inefficient combustion and increased fuel consumption.

- Rough idling and stalling: The ECU’s inability to adjust fuel injection timing and duration based on inaccurate pressure readings can result in inconsistent engine operation.

- Reduced power output: The engine may experience a loss of power due to inefficient combustion and improper ignition timing.

Q: What happens if the Turbo Boost sensor fails?

A: A malfunctioning Turbo Boost sensor can have serious consequences:

- Overboost: The ECU, lacking accurate boost pressure data, may not be able to control the boost control valve effectively, leading to excessive boost pressure and potentially damaging the engine.

- Underboost: A faulty Turbo Boost sensor can also result in insufficient boost pressure, leading to reduced power output and sluggish performance.

- Engine damage: Both overboost and underboost can significantly impact engine health, potentially causing severe damage to components like pistons, connecting rods, and turbocharger internals.

Tips for Maintaining Optimal Sensor Performance

- Regular Inspection: Regularly check for signs of damage or wear on both sensors, ensuring proper connection and sealing.

- Cleanliness: Keep the sensors clean and free of debris, as contamination can affect their accuracy.

- Professional Diagnosis: If you suspect a sensor malfunction, seek professional diagnosis and replacement.

- Quality Replacement Parts: Always use genuine or high-quality aftermarket replacement sensors to ensure optimal performance and longevity.

Conclusion: A Vital Partnership for Engine Performance

The MAP and Turbo Boost sensors, though distinct in their functions, work in tandem to ensure optimal airflow management in both naturally aspirated and turbocharged engines. The MAP sensor provides a comprehensive view of intake manifold pressure, while the Turbo Boost sensor specifically monitors the pressure generated by the turbocharger.

By leveraging data from both sensors, the ECU precisely controls fuel injection, ignition timing, and boost pressure, maximizing engine power and efficiency while protecting the engine from potential damage. Understanding the roles of these crucial components is essential for discerning drivers and mechanics alike, allowing for informed maintenance and troubleshooting, ultimately ensuring the smooth and reliable operation of modern engines.

Closure

Thus, we hope this article has provided valuable insights into Unveiling the Dynamics of Airflow: A Comprehensive Guide to Manifold Absolute Pressure and Turbo Boost Sensors. We thank you for taking the time to read this article. See you in our next article!