Unveiling the Secrets of Airflow Measurement: A Comprehensive Guide to MAF and MAP Sensors

Related Articles: Unveiling the Secrets of Airflow Measurement: A Comprehensive Guide to MAF and MAP Sensors

Introduction

With great pleasure, we will explore the intriguing topic related to Unveiling the Secrets of Airflow Measurement: A Comprehensive Guide to MAF and MAP Sensors. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

Unveiling the Secrets of Airflow Measurement: A Comprehensive Guide to MAF and MAP Sensors

The intricate dance of combustion within an internal combustion engine hinges on a precise balance of air and fuel. To achieve this delicate equilibrium, modern vehicles rely on sophisticated sensors that monitor and regulate the incoming air. Two prominent players in this critical process are the Mass Air Flow (MAF) sensor and the Manifold Absolute Pressure (MAP) sensor. While both contribute to the engine’s optimal performance, they employ distinct methodologies and have unique roles in the fuel delivery system.

This comprehensive guide delves into the workings of MAF and MAP sensors, exploring their respective functionalities, benefits, and limitations. Through a clear and informative exposition, we aim to demystify the intricacies of these crucial components, providing a deeper understanding of their impact on engine operation and vehicle performance.

The MAF Sensor: A Direct Measure of Airflow

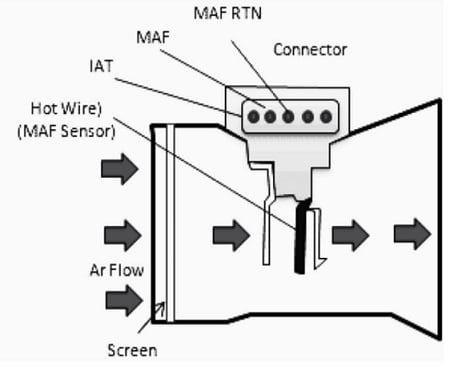

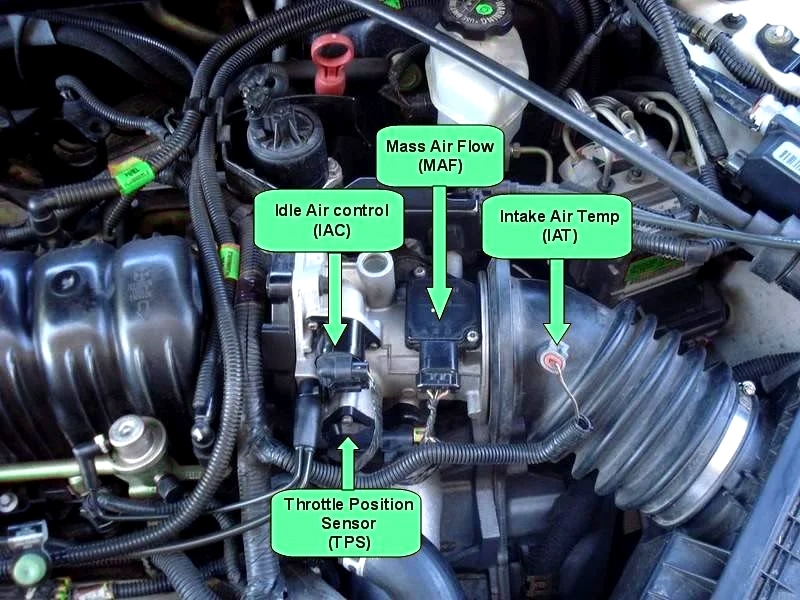

The MAF sensor, a cornerstone of modern engine management systems, directly measures the mass of air entering the engine. Positioned in the intake manifold, typically before the throttle body, the MAF sensor employs a heated element to determine the air’s mass flow rate.

The sensor’s operation relies on the principle of heat transfer. A heated wire element, often made of platinum or nickel, is embedded within the sensor. As air flows over the wire, it cools the element. The sensor measures the amount of electrical current required to maintain the wire at a constant temperature. This current directly correlates to the mass of air flowing past the wire, providing a precise measurement of airflow.

Benefits of the MAF Sensor:

- Accurate Airflow Measurement: The MAF sensor provides a highly accurate and real-time measurement of airflow, crucial for precise fuel injection control.

- Improved Fuel Efficiency: By accurately measuring airflow, the MAF sensor enables the engine control unit (ECU) to deliver the optimal amount of fuel, minimizing wasted fuel and maximizing fuel efficiency.

- Reduced Emissions: Precise fuel-air mixture optimization achieved through the MAF sensor leads to cleaner combustion, reducing harmful emissions.

- Enhanced Engine Performance: Optimal fuel-air ratios translate to smoother engine operation, increased power output, and improved acceleration.

The MAP Sensor: Indirectly Monitoring Intake Pressure

Unlike the MAF sensor, the MAP sensor does not directly measure airflow. Instead, it indirectly determines the amount of air entering the engine by measuring the pressure within the intake manifold. Located on the intake manifold itself, the MAP sensor is typically a diaphragm-based device.

The MAP sensor’s operation relies on the principle of pressure measurement. A diaphragm, often made of a flexible material, is sealed within the sensor. When pressure changes within the intake manifold, the diaphragm flexes. This flexing is detected by a sensor, usually a potentiometer or a strain gauge, which translates the pressure into an electrical signal.

Benefits of the MAP Sensor:

- Simpler Design: The MAP sensor is generally simpler in design and construction than the MAF sensor, making it more affordable to manufacture.

- Robustness: MAP sensors are known for their durability and resistance to environmental factors like dirt and moisture.

- Versatility: MAP sensors can be used in a wider range of engine applications, including turbocharged and naturally aspirated engines.

The MAF vs. MAP Debate: A Tale of Two Approaches

While both MAF and MAP sensors contribute to optimal engine operation, they offer distinct advantages and disadvantages.

MAF Sensor:

-

Advantages:

- High accuracy in airflow measurement.

- Enables precise fuel injection control.

- Contributes to improved fuel efficiency and reduced emissions.

-

Disadvantages:

- More complex and expensive to manufacture.

- Susceptible to contamination by dirt and oil.

- Can be affected by changes in air temperature.

MAP Sensor:

-

Advantages:

- Simpler design and lower cost.

- Greater durability and resistance to environmental factors.

- Versatility across various engine configurations.

-

Disadvantages:

- Less accurate than MAF sensors in airflow measurement.

- Can be less responsive to rapid changes in airflow.

- May require calibration for optimal performance.

Choosing the Right Sensor for Your Engine:

The choice between a MAF and a MAP sensor ultimately depends on the specific engine design and intended application.

- MAF sensors are typically preferred for engines where precise airflow measurement is critical, such as high-performance vehicles and those with complex fuel injection systems.

- MAP sensors are often employed in engines where cost-effectiveness and robustness are prioritized, such as older vehicles and those with simpler fuel injection systems.

FAQs about MAF and MAP Sensors:

1. What happens when a MAF sensor fails?

A malfunctioning MAF sensor can lead to a range of issues, including poor fuel economy, rough idling, hesitation during acceleration, and increased emissions. The engine control unit (ECU) may rely on default values for airflow, leading to an inaccurate fuel-air mixture.

2. Can I clean a MAF sensor?

While cleaning a MAF sensor can sometimes resolve performance issues, it is crucial to exercise caution. The sensor’s delicate components can be easily damaged by harsh cleaning solutions or improper handling. Consult the manufacturer’s recommendations or a qualified mechanic for guidance.

3. How do I know if my MAF sensor is bad?

Common symptoms of a faulty MAF sensor include:

- Check engine light illuminated with a code related to the MAF sensor.

- Reduced fuel economy.

- Rough idle or stalling.

- Hesitation or sluggish acceleration.

- Black smoke from the exhaust.

4. Can a MAP sensor be cleaned?

MAP sensors are generally not designed to be cleaned. If a MAP sensor is malfunctioning, it is usually recommended to replace it with a new unit.

5. What is the difference between a MAF and a MAP sensor?

The key difference lies in their measurement methods. A MAF sensor directly measures the mass of air entering the engine, while a MAP sensor indirectly determines airflow by measuring the pressure within the intake manifold.

Tips for Maintaining MAF and MAP Sensors:

- Regular Air Filter Replacement: A clean air filter prevents dust and debris from entering the intake manifold and contaminating the MAF sensor.

- Avoid Excessive Engine Oil Consumption: Excessive oil consumption can lead to oil buildup on the MAF sensor, impacting its performance.

- Use High-Quality Fuel: Using contaminated or low-quality fuel can lead to deposits forming on the MAF sensor.

- Avoid Harsh Cleaning Solutions: When cleaning a MAF sensor, use a gentle cleaning solution specifically designed for sensors and avoid harsh chemicals.

Conclusion:

The MAF and MAP sensors play vital roles in ensuring optimal engine performance by precisely regulating the fuel-air mixture. While both contribute to efficient combustion and reduced emissions, their distinct methodologies offer unique advantages and disadvantages.

Understanding the intricacies of these sensors empowers vehicle owners to diagnose potential issues and maintain their vehicles effectively. By recognizing the signs of a malfunctioning sensor and following recommended maintenance practices, drivers can ensure their vehicles operate efficiently and reliably. The choice between a MAF and a MAP sensor ultimately depends on the specific engine design and application, highlighting the importance of selecting the appropriate sensor for optimal performance and longevity.

Closure

Thus, we hope this article has provided valuable insights into Unveiling the Secrets of Airflow Measurement: A Comprehensive Guide to MAF and MAP Sensors. We thank you for taking the time to read this article. See you in our next article!